Battery Life, Performance & Sourcing Realities

New research from the American Transportation Research Institute (ATRI) analyzed the environmental impacts of Class 8 zero-emission trucks (ZETs). The research utilized federal and industry-sourced data to identify and compare full life-cycle CO2 emissions for a range of truck types:

- Internal combustion engine (ICE) trucks powered by diesel

- Battery electric vehicle (BEV) trucks powered by electricity

- Fuel cell electric vehicle (FCEV) trucks powered by hydrogen

ATRI’s analysis compared CO2 emissions across the full vehicle life cycle:

- Vehicle production

- Energy production and consumption

- Vehicle disposal/recycling

The study found that full life-cycle CO2 emissions for the battery electric truck would only generate 30 percent fewer emissions than the standard diesel truck.

The marginal environmental benefits of electric trucks are due, in large part, to lithium-ion battery production – which generates more than six times the carbon of diesel truck production. ATRI’s research concludes that hydrogen fuel cell trucks (FCEV) are ultimately the most environmentally friendly truck type, although the technology is not presently feasible for long-haul operations.

Data and charts courtesy of the American Transportation Research Institute.

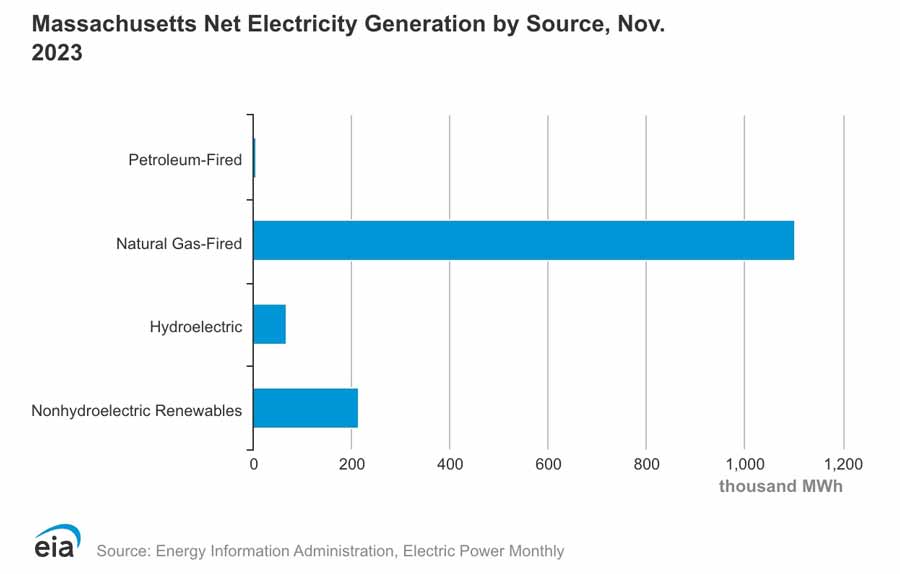

Massachusetts gets the majority of its electricity from burning natural gas. What is being done to protect communities around these power plants?

In reality, zero-emission is a false statement; the emissions for EVs in Massachusetts are still occurring in the communities around the natural gas plants.

"Zero Emissions" Realities

Is it possible for California to reach zero emissions by 2035? Why it matters to Massachusetts.

Massachusetts law requires the Commonwealth to adopt California motor vehicle emissions standards as long as those standards achieve, in the aggregate, greater emissions reductions than federal standards. Massachusetts adopted the California Low Emission Vehicle (LEV) program regulations in 1991 and has amended it many times to remain identical to the California LEV program. This latest amendment involves emission standards for Model Years 2025 and later medium- and heavy-duty vehicles and engines.

Massachusetts is one of 15 states and the District of Columbia to set a goal of 100 percent electric truck and bus sales by 2050.

The commercial transportation industry in Massachusetts continues to be at the forefront of environmental initiatives to bring safer and cleaner vehicles into the Commonwealth. The industry supports our state's efforts to do so.

Unfortunately, it seems that many issues and obstacles remain unresolved as we continue to push forward. The success of this initiative in California is still very much in question, and a formal report on its implementation is not required until 2028.

Why is Massachusetts moving forward when the feasibility of the CARB initiative in California is still very much in question? This short video highlights many thought-provoking topics that continue to be left unresolved in California and, therefore, in Massachusetts.

Truck Battery Realities

Battery Life

It is well understood that lithium-ion batteries begin to slowly degrade once the charging and discharging process commences, and the number of charge cycles greatly influences battery degradation. Separate from the number of charging cycles, there is evidence that the rate at which a BEV is charged could impact battery life. Because of operational constraints – such as driver hours-of-service – and the large energy capacity of a truck battery, faster charging may be necessary.

Sourcing Materials & Supply Chain Issues

Several key raw materials are needed for lithium-ion batteries; depending on the battery chemistry, these might include lithium, graphite, cobalt, manganese and nickel. While these materials are critical for batteries and for producing a large BEV national fleet, the U.S. is almost entirely dependent on other countries for these materials. Over the past decade, the U.S. has imported nearly 100 percent of the critical minerals needed for battery production from countries including China, Australia, Chile and the Democratic Republic of Congo.

Battery Performance

Ambient temperatures can affect the battery performance of electric vehicles. Cold weather slows the chemical and physical reactions that make batteries work, leading to longer charging times and a temporary reduction in range. Conversely, higher temperatures generally lead to faster chemical and physical reactions.

In addition, low or elevated temperatures can initiate the use of electric air conditioning or heating systems, which can draw significant amounts of battery power – with an accompanying reduction in driving range.

Topography also has a strong influence on energy consumption and battery operation as well. All vehicles expend more energy on an uphill grade than when traveling on level ground. Energy consumption for electric vehicles tends to steadily increase as road grade increases.

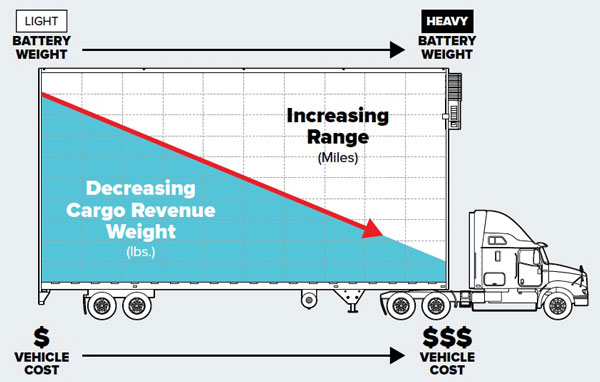

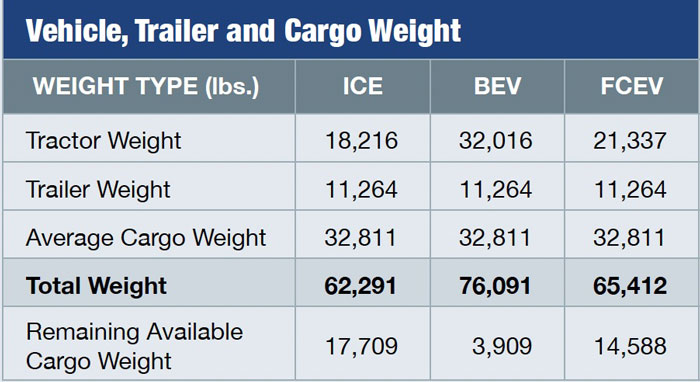

Battery Weight & Cargo Capacity

Battery weight may substantially limit the long-haul capabilities of a BEV, leading to a need for more BEV vehicles to carry the same amount of cargo. Those carriers operating closer to the maximum allowable weight will likely have to modify their operations if they wish to use long-haul battery electric vehicles.

Battery Materials & BEV Viability

Battery Materials Dominate BEV Viability

Tens of millions of tons of cobalt, graphite, lithium and nickel will be needed to replace the existing U.S. vehicle fleet, placing high demand on raw materials.

Depending on the material, this represents:

- 6.3 to 34.9 years of current global production.

- 8.4 to 64.4% of global reserves.

BEV production has considerable environmental and social impacts:

- Mining and processing produce considerable CO2 and pollution issues.

- In some operations, a minimum of one million gallons of water must be utilized to produce a single pound of lithium.

- Exploitation of labor is common in some source countries.

BEV Truck Conundrum

Battery weight increases price and vehicle range but decreases cargo revenue weight. Ultimately, more BEV trucks will be needed on already congested roadways to haul the same amount of freight.